Problem

Oakland University’s Industrial and Systems Engineering (ISE) Department has developed an educational model that prepares entry-level engineers, and up-skills working engineers, for Industry 4.0 careers. A key component of Oakland’s model is close academic/industry cooperation, as noted in the Wall Street Journal ( “This College Degree Brought to You By Amazon,” Nov. 9, 2020).

With the advent of Industry 4.0, industry faced the need to obtain new engineering graduates that not only understood Industry 4.0 concepts and techniques, but were also aware of, and capable of using, Industry 4.0 tools to apply these concepts and techniques. In addition, industry was looking for assistance to up-skill their existing engineers on Industry 4.0 concepts, techniques and tools.

Solution

The ISE Department developed an educational model that emphasizes a close academic/industry partnership to focus on educating 3 groups:

1) undergraduate engineer students,

2) graduate engineering students with emphasis on full-time working engineers,

3) non-degree students who are full-time working engineers.

Implementation

Background

In 2007, Oakland University’s ISE Department launched its ISE B.S.E. (one of six programs in the U.S. that is ABET accredited—the Accreditation Board for Engineering and Technology—in both Industrial Engineering and in Systems Engineering). The university also launched an ISE M.S. degree program at this time. The department took control of an existing Engineering Management M.S. program which it revised and relaunched in 2011. It also offers a Systems Engineering Ph.D. program. In 2017, it began offering a Systems Engineering M.S. degree. All graduate programs are offered on the evenings, and approximately 85% of the 200 graduate students are full-time working engineers engaged in life-long learning. According to the U.S. Bureau of Labor Statistics, there were just over 25,000 ISEs working in Michigan in 2020, compared with about 40,000 MEs and 12,000 EEs.

Creating a Curriculum

With the assistance of the department’s Industrial Advisory Board as well as several engineering and manufacturing companies, ISE faculty created a curriculum to emphasize Product Lifecycle Management (PLM ). PLM is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal. This was before the term “Industry 4.0” emerged. At that time, Product Lifecycle Management was the commonly used term for the concepts, techniques and tools that would first be referred to as Industry 4.0 in 2011. Hence, “PLM” is used in the title of several of the department’s Industry 4.0-related courses.

The concept of Industry 4.0 used by the ISE Department in developing its education program involves separating it into two layers:

1) Technical layer: Considers the use of various Industry 4.0 software tools used to create digital twins—including production lines, ergonomics, robotics, manufacturing cells, etc. The ISE Department focus is primarily on the use of these digital twin software tools in performing engineering analysis, rather than on just the operation of the tools themselves (e.g., using a production line’s digital twin to do a bottleneck analysis).

2) Coordination layer: Considers the storage and handling of all data and decisions from the various Industry 4.0 digital twin tools, users and decision makers on the technical layer. The data is stored in a single database, where all interactions between the software tools and their users with this database, as well as between the users and various decision makers, is coordinated by an Industry 4.0 software tool.

Outcome

Phase 1: The initial phase in developing this educational model involved integrating Industry 4.0 concepts, techniques and tools into existing courses. After initially working with another PLM software company, the department joined the Siemens Academic Partnership Program in 2011. Through its involvement in the program, the department obtained access to the Tecnomatix suite of software tools and Teamcenter, as well as access to training and technical assistance from Siemens.

The three main Industry 4.0 software tools used from the Tecnomatix suite were all focused on the technical layer:

- Jack – ergonomic digital twin software

- Plant Simulation – discrete event digital twin software

- Process Simulate – robotics and manufacturing cell digital twin software

Teamcenter is a coordination layer Industry 4.0 software tool and is used to manage product and manufacturing requirements as well as store and maintain all digital data generated during a product’s lifecycle.

Initially, the ISE Department began integrating these Industry 4.0 software tools into a variety of existing courses starting with EGR 2600 Introduction to Industrial and Systems Engineering. EGR 2600 is a second-year course that is required for all Computer Engineering, EE, ME and ISE students. Both Plant Simulation and Jack are used in this course. In it, students are given assignments to construct and analyze digital twins using Plant Simulation or Jack that demonstrate the effects of random behavior on realistic manufacturing systems.

In order to complete a given EGR 2600 assignment, students are given an associated Plant Simulation or Jack assignment user manual containing detailed instructions on how to use the particular Industry 4.0 tool to complete that assignment. Hence, the focus is on using the Industry 4.0 tool to perform the desired analysis, not on how to operate the tool.

Some other courses in which these Industry 4.0 tools were introduced include:

- ISE 3341 Ergonomics and Work Design (Jack)

- ISE 4469/5469 Computer Simulation of Discrete Event Systems (Plant Simulation)

- ISE 5560 Product Lifecycle Management (Teamcenter)

- ISE 4422/5422/ME 4740 Robotic Systems (Process Simulate)

In some of these courses, students complete assignments using a particular Industry 4.0 tool while in other courses the use of a particular tool is demonstrated.

Phase 2: The next phase in developing the educational model involved the development of new courses that directly teach Industry 4.0 tools and their application. A few years after the introduction of the Industry 4.0 software tools into its existing courses, the ISE Department conducted an assessment of their effectiveness. Feedback received from students, alumni and employers of alumni noted that while it was very positive that students were using these tools (something that these companies were not seeing from other universities), it would be an improvement if students were given the opportunity to learn more about how to use the various Industry 4.0 tools, that is, take a “deeper-dive” into the tools.

This feedback led to the development of new ISE courses that would focus on how to operate Industry 4.0 tools as well as on their application. These courses would have aspects of both training (i.e., learning how to operate the tool) as well as education (i.e., learning how to apply the tool), and are titled PLM Applications courses (again, many were created before the term “Industry 4.0” was widely accepted).

The ISE Department obtained funding from the Michigan Economic Development Corp. in 2012 for a PLM/MSV Training and Internship Program. The goal was to develop and offer the first PLM Applications course with a focus on ergonomics, PLM Applications – Ergonomics. The pilot course was developed and first offered in executive style (i.e., 8 hours/day over 5 consecutive days). In order to maintain the close academic/industry partnership in developing curriculum, the pilot course’s content was developed in close cooperation with an engineering consulting firm while half of the pilot course’s attendees were ISE Department students, and the other half were working engineers from an automotive OEM.

Feedback from the pilot course’s assessment was extremely positive from both the ISE students and the working engineers, resulting in the creation of a series of PLM Applications courses focusing on the operation and application of various Industry 4.0 tools. These PLM Applications courses meet for half the time of other ISE courses, 7 weeks (4 contact hours per week) rather than the 14 weeks for other ISE courses. Since they are elective, students select them based on their interests and career goals.

The following six PLM Applications courses have been developed to-date and are currently, or were recently, offered:

- ISE 4461/5461 PLM Applications – Product Data Management (uses Teamcenter)

- ISE 4462/5462 PLM Applications – Robotics (Process Simulate)

- ISE 4463/5463 PLM Applications – Ergonomics (Jack)

- ISE 4466/5466 PLM Applications – Change Management (Teamcenter)

- ISE 4467/5467 PLM Applications – Throughput Simulation (Plant Simulation)

- ISE 4900/5900 PLM Applications – Manufacturing Process Planning (Teamcenter)

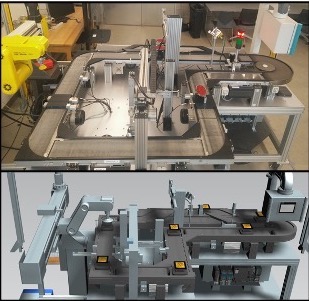

One of the ISE 4467/5467 PLM Applications – Throughput Simulation class projects involve analyzing the performance of an automated manufacturing system using its digital twin. Photos of this manufacturing system (located in the ISE Dept.’sSharf Computer-Integrated Manufacturing Lab) and its Plant Simulation digital twin are shown below.

Feedback from ISE Department’s core stakeholders (students, faculty, alumni and companies) has been very positive with respect to these PLM Applications courses. An illustration of their value to industry is the willingness of local companies to enroll their engineers into individual courses as non-degree students.

Anecdotal evidence of this success includes a Southeast Michigan based automotive OEM hiring an Oakland University ISE graduate as their first Digital Manufacturing Engineer. This company and other OEMs have hired many ISE graduates to various Industry 4.0-related engineering positions. A German-based tier 1 supplier hired an ISE graduate to work in their Auburn Hills Engineering Center as the first Digital Industrial Engineer in their world-wide operations. Several other companies in Southeast Michigan, both automotive and non-automotive, have hired ISE graduates to Industry 4.0-related engineering positions. In addition, these companies have been sending their working engineers to enroll in ISE Department Masters’ programs.

Phase 3: This phase involves the development of an Industry 4.0 dual education program with industry. A traditional dual education system combines apprenticeships in a company with education at a vocational school. This system is practiced in several countries, primarily in Europe. The ISE Department has developed a variation on this concept in its Industry 4.0 Internship Program. This internship program combines university-based learning with industrial experience.