Problem

The primary objective of any factory has always been to continuously increase productivity. This intention is being expedited by digitalization, as new possibilities and, in some cases, disruptive changes provide significant potential. If companies want to keep pace and remain competitive in the long term, they must participate in the digital transformation.

In the Digital Factory, it is possible to increase productivity in different ways. Flexibility in production plays an important role. In an adaptable, fully networked manufacturing setup that can respond quickly to new requirements and volatile markets, downtimes can be reduced considerably, for example, by comprehensive diagnostic options, which significantly increases system availability.

While in the past the aim was to reduce costs and increase productivity with mass production and large batch sizes, changing customer needs and the desire for greater individuality now require a different approach. Here, cost advantages can only be achieved through the economical manufacturing of very small quantities and through provision of the necessary flexibility. Furthermore, the focus is on “Idea to cash”: How quickly do investments in digitalization pay off? What’s more, to develop new business models or redesign processes from the ground up, and thus harness the full potential of digitalization, you need to think outside the box.

Solution

The key to a successful Digital Factory lies in the data and having the right mindset. They provide the basis for companies to benefit from the advantages – including increased system availability, resource- and energy-saving manufacturing methods, and higher-quality processes – while simultaneously being able to master the current challenges.

With universally available standardized data and a suitable, secure digital infrastructure, Phoenix Contact laid the foundations for a Smart Factory at its Bad Pyrmont site in Germany.

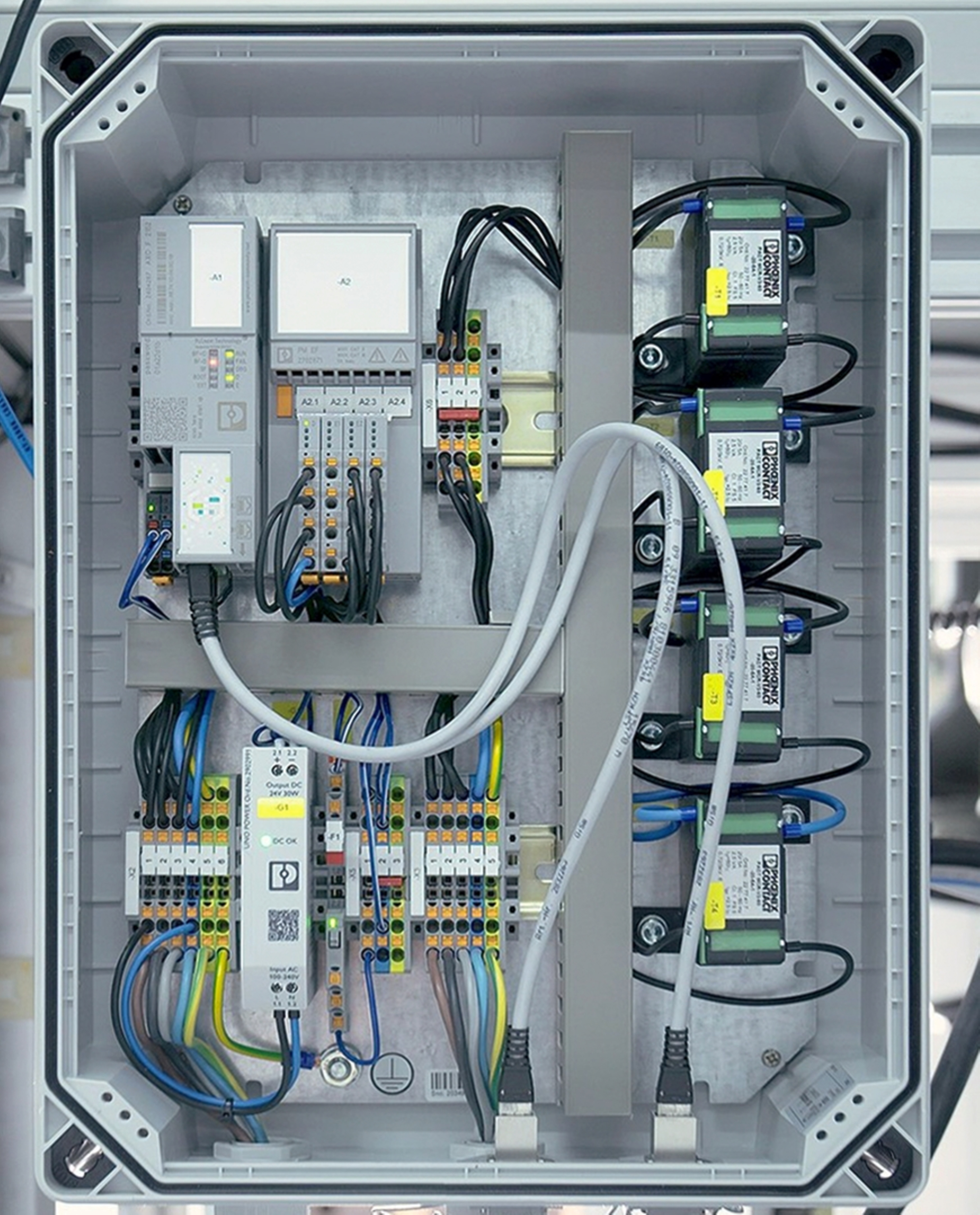

For the first steps toward this goal, the automation specialists brought together PLCnext, WLAN, network technology, HMI, safety, and many other products from Phoenix Contact in the Smart Production Cabinet. In combination with the company’s own automation standard, Smart Production Library, the cobot applications were integrated into the manufacturing network in half the time.

Furthermore, the use of automated guided vehicle systems has increased the flexibility of material transport. Phoenix Contact also equips these systems with its own WLAN technology and is already in the process of testing the use of other technologies.

Implementation

Efficient Data Collection

The first step in creating a Digital Factory is the collection of data. This requires a solution that does not jeopardize the CE certification of existing machines nor the warranty of new machines. When it comes to saving and evaluating the acquired data, many different interfaces need to be taken into consideration, as the traditional separation of the OT and IT levels is now a thing of the past. On the Internet, all things are networked and can communicate with each other. This results in numerous advantages, such as the ability to analyze data using artificial intelligence (AI), which enables a more efficient and effective decision-making process. However, comprehensive networking inevitably leads to communication problems between cloud services, ERP and MES systems, local databases, and the machine control system. In addition, each interface costs money.

The IIoT framework from Phoenix Contact, based on PLCnext Technology, provides the solution, as it builds a bridge between the OT and IT levels. In addition to efficient data collection, it enables smooth data exchange between all the systems and devices that belong to both of these worlds. To do this, the data is standardized so that it is available transparently on all levels and can be used in the production process in a useful way. Due to the open architecture, the IIoT framework can be extended flexibly.

Reliable and Secure Data Flow, Plus Easy Machine Integration

From the sensor to the cloud: Data is generated in all levels of the Digital Factory. However, the constantly growing number of devices and the amount of associated data result in increasingly complex networks. But the essential prerequisites for smooth manufacturing are efficient and reliable data flow, and a high degree of flexibility. They also ensure the potential expansion of the solution in the future. New technologies – such as Bluetooth LE, LoRaWAN, 5G, or WLAN 6 – are required in order to benefit from innovative concepts such as the integration of Smart Devices, and to manage the growing bandwidth.

Connecting all network devices to the Internet provides many advantages for production, such as easy access to all machines from any location. However, with the growing number of nodes and amount of data involved, there is also a greater risk of unauthorized access by third parties. It is therefore absolutely essential that manufacturing operations are fully protected. When establishing security measures, it is also essential to create a bridge between the OT and IT worlds, and that the differing priorities, requirements, and workflows of the two are harmonized. Phoenix Contact has been certified in accordance with the IEC 62443 international series of standards for IT security. Here, the automation specialist offers various solutions that provide the necessary protection against attacks – whether from inside or outside the company – ranging from a comprehensive security concept and secure remote access to the protection of older machines that can no longer be updated (Figure 3).

The targeted use of production data is crucial for the flexible control of material flow in manufacturing and the ability to respond quickly to any changes. Shorter product lifecycles require intelligent solutions for the simple horizontal and vertical integration of machines or workstations – while at the same time standardization ensures that only a small amount of engineering effort is involved. The integration of innovative systems, such as cobots or automated guided vehicle systems, transform the Digital Factory into a Smart Factory,i.e., a self-organizing factory where assets can handle different tasks independently (Figure 4).

Space-Saving Data Collection Box

Above all, the digitalization of in-house production operations means having the courage to make changes. New processes can be tried out, and established processes can be put to the test. Therefore, for the digitalization of Phoenix Contact’s in-house manufacturing operations, the aim was to not only establish new technologies and innovative technical solutions, but to also foster a new mindset and attitude in the company. Electronics production at the Bad Pyrmont site involves 228 workstations daily. The retrofittable data collection boxes that were developed in-house provide a data collection solution that is a space-saving and inexpensive concept. Due to its compact design, the box can be recessed in the raised floor, for example. Furthermore, the data that needs to be collected is intercepted outside of the machines, thereby preventing any CE violations or loss of warranty. Each day, 1.3 million data points are accumulated in this way, totaling more than 270 Terabytes per year. Using the PLCnext Technology IIoT framework, the OT data can be consolidated with the higher-level (IT) systems – such as ERP or MES – and cloud services. However, the intelligent, self-learning anomaly detection algorithm from Phoenix Contact, as well as the solutions from various start-ups, showed that three to five percent of the inputs and outputs already enable effective analysis of the system. A user-friendly visualization of the results now shows the production manager and his team where there is room for optimization in day-to-day business operations and recommends actions that can be taken to harness this potential.

50% Saving with Network Integration

Another measure at the Bad Pyrmont manufacturing site was the creation of a future-proof digital network infrastructure, enabling comprehensive diagnostic options and redundancy to be implemented for failsafe performance. A ring topology with Gigabit capability was created using the latest generation of managed switches from Phoenix Contact.

The individual machines are connected to the higher-level production network using a Gigabit firewall. This protects against unauthorized access and allows the machines to be integrated into the company network without their IP parameters having to be changed. Using the built-in firewall assistant, new machines can even be integrated into the existing production plants without more advanced IT skills being required. This means that they can only communicate with the higher-level production network via the approved protocols and ports.

Outcome

Phoenix Contact’s Digital Factory provides the answer to the key questions surrounding digitalization and is helping to drive the vision of the “All Electric Society” forward by optimizing processes, resources, and consumption. Interoperable architectures, an open control platform, and use of the latest technologies in combination with a flexible, secure infrastructure. The digital reproducibility of products enables consistent digital engineering chains and innovative Smart Services for the creation of an efficient and sustainable Smart Factory, and for networking with other sectors.

“Thanks to our Digital Factory solutions, we were able to increase the productivity of our in-house production processes by more than ten percent within just a year and a half. And we have identified even more untapped potential that we plan to explore in the coming years,” said Dr. Till Potente, Senior Director Production and Engineering IMA, Phoenix Contact Electronics, GmbH.